In any machining process, the spindle is one of the most critical components of a machine tool. It is the heart of CNC machines, milling machines, lathes, and machining centers, responsible for holding and rotating cutting tools or workpieces at precise speeds. The performance of a spindle directly affects machining accuracy, surface finish, and overall production efficiency.

Choosing the right type of spindle is essential not only for achieving high precision but also for improving productivity and reducing downtime. Different spindles are designed to meet specific machining requirements, such as high-speed cutting, heavy-duty operations, or long-duration continuous machining. Understanding the types of machine spindles, their advantages, and their applications will help manufacturers, engineers, and workshop operators make informed decisions that optimize their machining processes.

Machine spindles come in various designs, each engineered for specific machining applications. Choosing the right spindle type can significantly improve machining efficiency, precision, and tool life. Here are the most common types of machine spindles and their key features:

Belt-driven spindles are one of the most traditional types, featuring a motor connected to the spindle via a belt system.

Advantages: Simple design, lower cost, easy maintenance.

Applications: Suitable for medium to low-speed machining tasks where high torque is not critical.

Limitations: Speed fluctuations can occur due to belt stretch or wear, making them less ideal for high-precision operations.

Direct-drive spindles connect the motor directly to the spindle, eliminating belts or gears.

Advantages: High-speed operation, excellent precision, and fast acceleration/deceleration. Minimal energy loss during transmission.

Applications: Ideal for high-speed milling, precision drilling, and finishing operations.

Limitations: Higher cost and more complex design compared to belt-driven spindles.

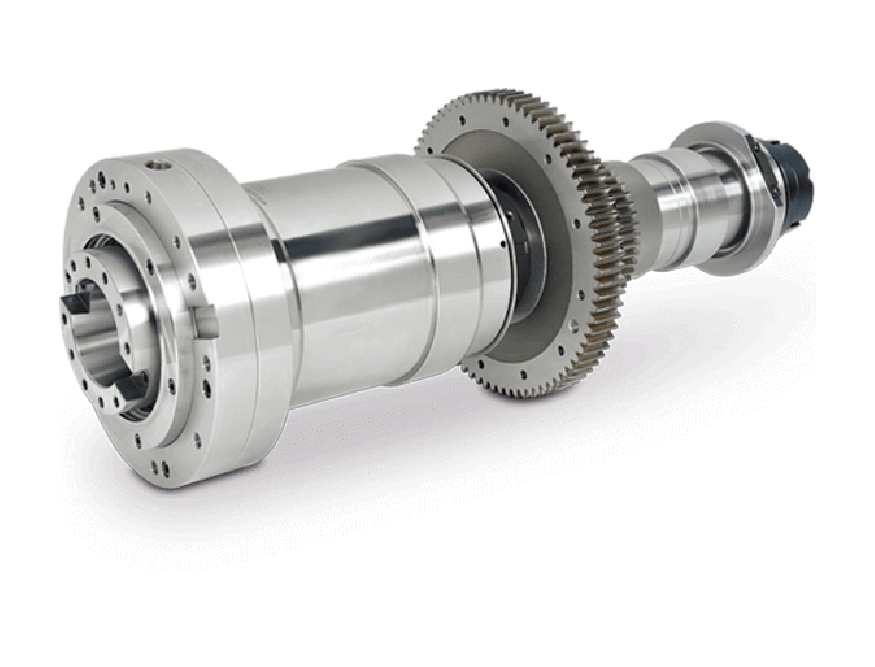

Gear-driven spindles use a gear mechanism to transfer power from the motor to the spindle.

Advantages: High torque output, stable performance under heavy loads, and precise speed control.

Applications: Suitable for heavy-duty machining, such as roughing, large material removal, and high-load operations.

Limitations: More complex maintenance due to gears and lubrication requirements.

Air-cooled spindles use a flow of air to dissipate heat generated during operation.

Advantages: Compact design, lightweight, and simple maintenance.

Applications: Ideal for small CNC machines or situations where space is limited.

Limitations: Cooling efficiency is lower compared to water-cooled spindles, making them less suitable for long-duration high-speed operations.

Water-cooled spindles use a circulating liquid to maintain consistent spindle temperature.

Advantages: Superior heat dissipation, stable performance during long or high-speed operations.

Applications: Perfect for high-speed machining, long production runs, and high-precision tasks.

Limitations: Requires a water circulation system and regular maintenance, leading to higher setup complexity.

Selecting the right spindle is crucial for achieving optimal machining performance, precision, and productivity. Different machining tasks and materials require different types of spindles. Here are key factors to consider when choosing a spindle for your machine:

Metal: Hard metals like steel and titanium often require high-torque or gear-driven spindles for roughing and high-load operations.

Plastics or Wood: Lighter materials can be machined effectively with belt-driven or air-cooled spindles at moderate speeds.

Composites: High-speed direct-drive spindles are often preferred for precise cutting without generating excessive heat.

High-speed machining: Direct-drive or water-cooled spindles provide stable performance at high RPMs.

Precision-focused tasks: Choose spindles with minimal runout and vibration, such as direct-drive spindles or precision gear-driven spindles.

Available machine space: Air-cooled spindles are compact and suitable for smaller machines, while water-cooled spindles need additional room for cooling systems.

Drive system compatibility: Ensure the spindle type matches the motor and control system of your CNC machine.

Short-duration or intermittent operations: Air-cooled spindles are often sufficient.

Continuous high-load operations: Water-cooled spindles are recommended to maintain consistent temperatures and prevent thermal expansion that can reduce precision.

Initial investment: Belt-driven spindles are cost-effective, while direct-drive and water-cooled spindles have higher upfront costs.

Maintenance requirements: Some spindles, like gear-driven and water-cooled spindles, need more frequent servicing and lubrication.

Long-term efficiency: Investing in a higher-quality spindle can reduce downtime and improve machining quality over time.

By evaluating these factors—material, speed, precision, machine compatibility, cooling, and budget—you can select the spindle type that best fits your machining requirements. Proper spindle selection not only enhances productivity but also extends the life of your machine and cutting tools.

Proper maintenance of machine spindles is essential to ensure long-term performance, consistent precision, and reduced downtime. Regular inspection of spindle rotation, vibration, and runout can help detect early signs of wear or misalignment, preventing costly repairs. Keeping the spindle clean from dust, chips, and coolant residue is equally important, as contamination of bearings and sealing surfaces can negatively affect accuracy and overall performance. Lubrication should be performed according to the manufacturer’s guidelines, with oil or grease replaced at recommended intervals to prevent overheating and bearing damage.

Temperature management is another critical aspect of spindle care. For high-speed or long-duration operations, it is important to ensure proper airflow for air-cooled spindles and effective water circulation for water-cooled spindles to maintain stable operating temperatures. Additionally, careful handling during transport and proper storage when machines are idle will help prevent shocks, corrosion, or bearing damage. Consistent maintenance not only prolongs spindle lifespan but also protects your CNC machine investment while ensuring reliable, high-precision machining results.

Choosing the right spindle type is a critical decision that directly impacts machining efficiency, precision, and overall productivity. By understanding the differences between belt-driven, direct-drive, gear-driven, air-cooled, and water-cooled spindles, manufacturers and workshop operators can select the optimal spindle for their specific materials, machining speeds, and load requirements. Proper spindle selection ensures not only better machining quality but also longer equipment lifespan and reduced downtime.

Equally important is regular spindle maintenance, including cleaning, lubrication, temperature monitoring, and careful handling. Consistent care helps maintain accuracy, prevents unexpected failures, and protects your investment in CNC machines. When selecting spindles, it is also recommended to work with reputable suppliers who provide high-quality, precision-engineered components. By combining the right spindle choice with proper maintenance practices, you can achieve reliable, high-performance machining results while maximizing the return on your equipment investment.