卧式镗床是现代制造业必不可少的机床,用于高精度加工大型、重型工件。航空航天、汽车和重型机械制造等行业都依赖这些机床来生产发动机零件、轴承座和机床床身等部件。

卧式镗床究竟是用来做什么的?为什么它对某些行业至关重要?

选择错误的机器会导致精度问题和效率低下,从而影响整个生产过程。

本文将阐述卧式镗床的功能、应用以及在选择满足生产需求的卧式镗床时需要考虑的关键因素。

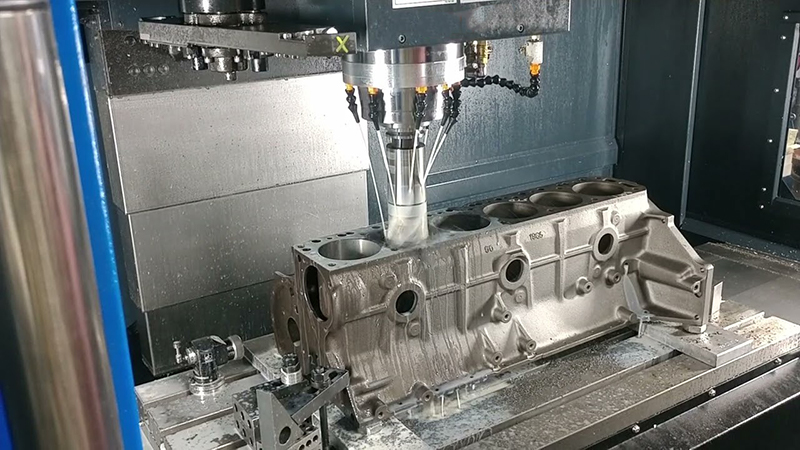

卧式镗床专为加工大型重型工件而设计,其特定功能对于确保精度、效率和耐用性至关重要。这些机床用于高精度加工,例如在工业机械零件、发动机缸体和重型机械部件上加工大孔。

为了高效运转,卧式镗床必须具备高切削力、高稳定性和高精度。加工铸件和钢结构等大型工件需要坚固的结构、精确的导向系统和高扭矩能力。此外,该机床还必须配备动力强劲的主轴和宽大的工作台,以适应各种尺寸的工件。

选择一台缺少必要功能的机床会导致加工质量差,例如表面粗糙、孔径不准以及尺寸精度降低。不合适的机床还可能导致磨损加剧、刀具寿命缩短,甚至设备故障。因此,了解满足您所在行业和应用特定需求的机床功能至关重要。

卧式镗床因其能够精确加工大型重型工件,在各行各业都发挥着至关重要的作用。以下是这些机床的主要应用:

卧式镗床常用于加工工业机械中的大型零部件,例如发动机缸体、变速箱和机床床身。由于这些零部件尺寸大、结构复杂,因此需要高精度和高稳定性。

为什么使用卧式镗床:

该机床切削力强、主轴稳定、导向系统精确,是加工大型、重型零件的理想选择,能够满足严格的公差要求和精细的表面光洁度要求。

在航空航天工业中,卧式镗床用于加工飞机发动机零件、机翼零件和支撑结构等关键部件。

为什么使用卧式镗床:

航空航天零部件对精度和稳定性要求极高。卧式镗床振动小、精度高,能够满足安全性和性能方面的严格标准。

汽车行业依赖卧式镗床加工发动机部件、变速箱壳体和其他大型机械零件。这些零件通常需要高精度和一致性,以确保车辆的正常运行。

为什么使用卧式镗床:

卧式镗床能够提供加工大型零件所需的动力,同时保持汽车应用所需的精度和质量。

在重型机械制造中,卧式镗床用于加工大型、坚固的零件,这些零件用于采矿机械、建筑机械和工业机械等设备。

为什么使用卧式镗床:

这些机器的设计旨在精确处理大型、重型部件,提供生产重型机械复杂零件所需的稳定性和切削力。

因素 | 为什么这很重要 | 最佳实践/建议 |

加工精度 | 高精度对于卧式镗床至关重要。 | 选择一台具有精确导向系统和精细控制的机器。 |

工件尺寸 | 工件的尺寸决定了机床的工作台和加工范围。 | 对于大型工件,请选择工作台面较大的机器。 |

切割力 | 该机器必须能够有效处理不同的材料。 | 对于较硬的材料,请选择功率更大的机器。 |

自动化级别 | 自动化可以提高生产效率。 | 根据您的需求选择具有自动化功能的机器。 |

卧式镗床 卧式镗床具有诸多优势,使其成为需要对大型、重型零件进行高精度加工的行业中不可或缺的设备。以下是使用卧式镗床的主要优势:

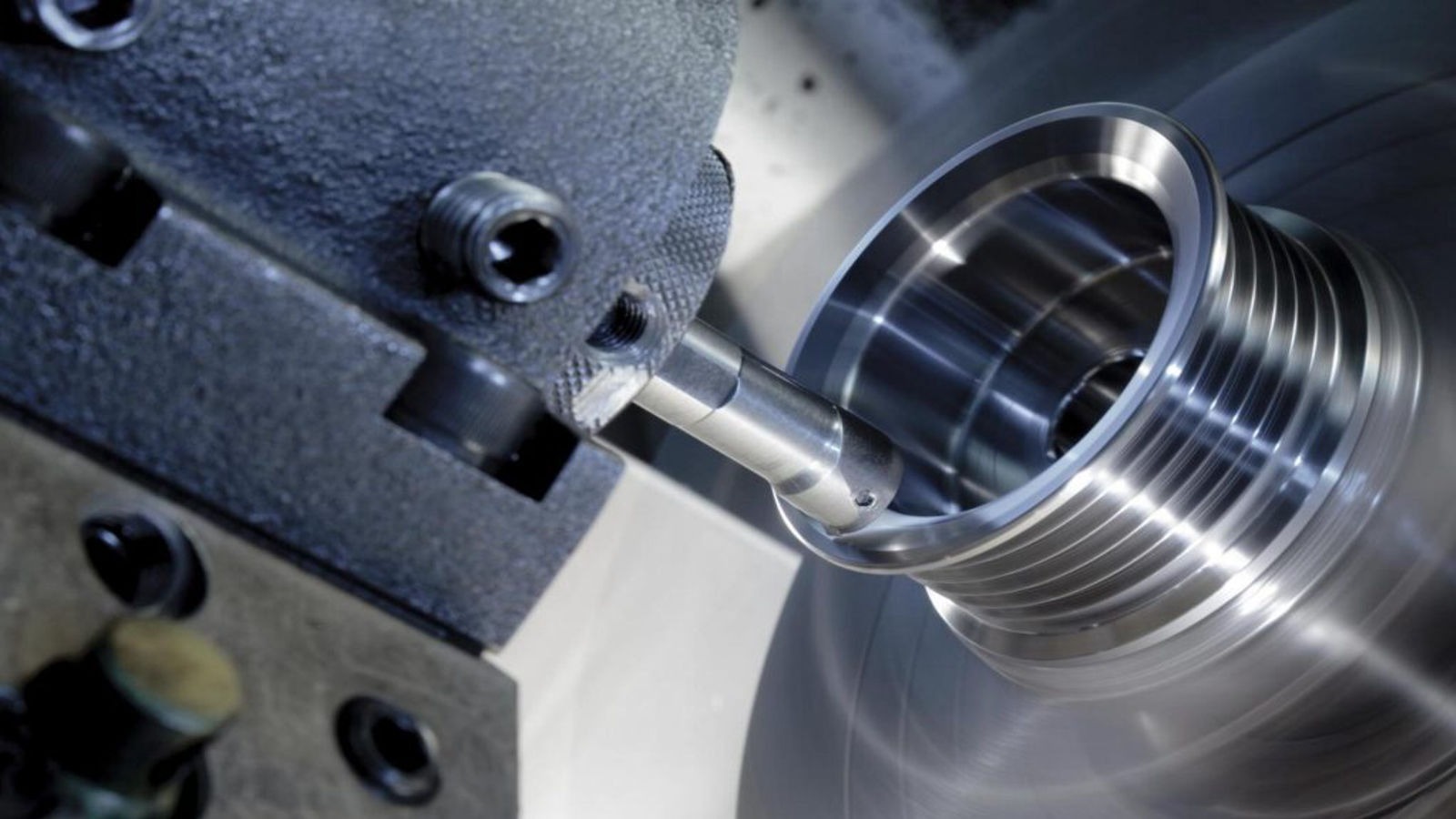

卧式镗床旨在实现高精度加工,确保大型零件按照精确规格进行加工。先进的导向系统、刚性结构和极低的振动,可实现高精度的孔定位、表面光洁度和公差控制。

这些机器专为加工大型重型工件而设计。它们宽大的工作台、坚固的框架和强劲的主轴,使它们能够加工诸如发动机缸体、变速箱和机床床身等超大型部件,而不会影响稳定性或精度。

卧式镗床在速度和性能方面都非常高效。其自动化功能,例如数控系统和自动换刀装置,减少了人工干预的需求,从而缩短了加工周期,提高了产量,并降低了人工成本。这使其成为大批量生产环境的理想选择。

卧式镗床凭借其稳定、精准的切削能力,能够加工出光滑、高质量的表面。加工精度高,减少了后续抛光或人工调整等繁琐的加工工序,从而节省了时间和运营成本。

卧式镗床用途广泛,能够加工多种材料,包括铸件、钢材和其他高韧性材料。它们可应用于航空航天、汽车、重型机械和工业机械制造等各个行业,加工各种具有不同要求的零部件。

在选择和使用卧式镗床时,避免常见错误有助于防止代价高昂的事故、停机和质量问题。以下是最常见的误区以及避免方法:

工作台太小可能无法正确支撑大型或重型工件,导致不稳定和加工不准确。

如何避免:

务必评估典型工件的最大尺寸和重量,并选择工作台尺寸和承载能力足够的机器。

选择主轴功率或结构刚性不足的机器会导致振动、表面光洁度差和精度降低——尤其是在加工硬质材料时。

如何避免:

确保机器具有足够的主轴功率、扭矩和刚性结构,以处理目标材料和切削深度要求。

不考虑自动化功能可能会导致过多的人工操作、更长的循环时间和不一致的加工结果。

如何避免:

评估您的生产量和工艺复杂度。对于批量或大批量生产,优先考虑配备数控系统、自动换刀装置和可选测头系统的机床。

仅仅根据价格选择机器可能会导致长期成本增加,因为会出现维护问题、效率降低或功能受限等问题。

如何避免:

要考虑总拥有成本,包括生产力、可靠性、维护和未来可扩展性——而不仅仅是购买价格。

购买仅满足当前需求的机器可能会限制日后的扩展或新项目能力。

如何避免:

选择一台具有足够灵活性和产能的卧式镗床,以满足未来发展、加工更大零件或更复杂加工任务的需求。

1. 卧式镗床主要用于什么用途?

卧式镗床主要用于加工大型重型工件,尤其适用于镗孔、钻孔、铣削和端面加工等大孔加工。它常用于发动机缸体、变速箱、机床床身和结构件的加工。

2. 卧式镗床和立式镗床有什么区别?

卧式镗床更适合加工需要强力支撑和稳定性的长、重、大型工件。立式镗床通常用于加工直径大但高度较矮的圆形零件,例如法兰或环。

3. 卧式镗床可以进行铣削加工吗?

是的。现代卧式镗床可以执行多种操作,包括镗孔、钻孔、铣削、攻丝和端面加工,使其在复杂的加工任务中具有很高的通用性。

4. 卧式镗床可以加工哪些材料?

卧式镗床可以加工多种材料,包括铸铁、碳钢、合金钢、不锈钢和大型焊接结构。

5. 如何选择合适尺寸的卧式镗床?

您应考虑工件的最大尺寸、重量、所需行程范围和加工精度。机床的工作台尺寸、主轴功率和刚性应满足您的典型生产需求。

6. 哪些行业最常使用卧式镗床?

卧式镗床广泛应用于重型机械制造、航空航天、汽车、能源设备、造船和工业机械生产等行业。

卧式镗床是现代制造业加工大型、重型、高精度零件的必备设备。其刚性强、切削性能稳定、功能多样,使其成为重型机械、航空航天、汽车和工业设备生产等行业的可靠解决方案。

选择合适的卧式镗床不仅仅是根据尺寸或价格来选择机器——它还需要将加工精度、切削力、工作台容量和自动化程度与您的实际生产需求相匹配。正确的选择可以显著提高效率、减少返工,并确保长期的加工稳定性。

如果您正在评估适合您车间的卧式镗床,或者计划升级现有设备,与经验丰富的专家合作可以帮助您避免代价高昂的错误,并选择真正适合您应用需求的解决方案。尽早寻求专业建议可以显著提高设备性能和投资回报率。