您知道吗?近 90% 的汽车制造流程都涉及某种形式的 CNC 加工。从发动机缸体到传动系统,CNC 机床是汽车创新的核心。在当今快节奏的世界中,汽车制造商追求速度、精度和灵活性——而 CNC 加工恰好能够满足这些要求!

在本文中,我们将探讨如何 数控机床 机械加工在汽车行业的应用、它们带来的优势以及这项重要技术的未来发展方向。无论您是汽车经销商、制造商,还是仅仅对现代机械加工感兴趣,本指南都能为您提供丰富的见解。

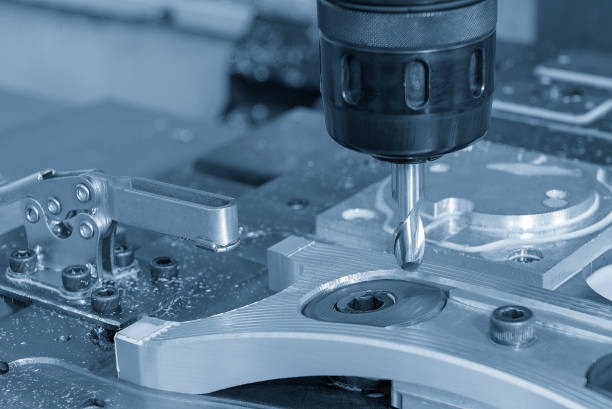

CNC(计算机数控)机床在现代汽车制造中发挥着至关重要的作用。从大批量零部件的批量生产到复杂零件的精密加工,CNC技术已成为该行业的支柱。如果没有CNC机床,汽车公司几乎不可能达到如今的速度、精度和一致性水平。

首先,数控机床确保精度和可重复性。在汽车生产中,即使是最小的偏差也可能影响性能或安全性。数控加工可以消除人为错误,并确保从发动机缸体到刹车盘的每个部件都符合严格的行业标准。

其次,数控机床能够实现大批量、大规模生产。汽车工厂依靠 数控设备 以无与伦比的效率生产数千个相同的零件。这种一致性对于装配线至关重要,因为装配线上的零部件必须完美地装配在一起。

第三,CNC技术支持设计和原型制作的灵活性。汽车制造商不断创新——无论是电动汽车、混合动力汽车,还是轻量化节能车型。CNC机床使工程师能够快速测试和改进新设计,从而缩短从概念到生产的时间。

最后,CNC加工可以提高成本效益和可靠性。虽然初始投资可能较高,但CNC机床可以减少浪费、优化材料利用率并最大程度地减少停机时间,从而降低总体生产成本并提高制造商的盈利能力。

数控机床在生产关键和辅助汽车零部件方面都不可或缺。它们能够处理复杂的几何形状、保持严格的公差,并能处理各种材料,这使得它们在汽车制造的几乎每个阶段都必不可少。以下是数控加工在汽车领域的主要应用:

发动机缸体——数控铣削和钻孔为气缸、冷却和润滑创建精确的腔体和通道。

气缸盖——按照精确的规格加工,以确保适当的气流和燃烧效率。

活塞和曲轴——采用高精度生产,确保耐用性和平稳的性能。

齿轮——数控车削和滚齿确保齿形准确,从而实现平稳的动力传输。

轴 – 经过机械加工以确保传动组件内的强度和精确对准。

外壳——CNC 加工保证适当的配合和密封,以实现长期可靠性。

刹车盘和刹车鼓——需要高精度加工以保持平衡并避免振动。

卡钳——经过精确加工,确保制动力一致。

ABS 组件 – CNC 加工可为电子和液压集成提供严格的公差。

控制臂和转向节——经过机械加工,可承受高负荷和高压力。

转向齿条和外壳——需要精确加工以确保平稳操控和安全性。

减震器组件——采用精确的公差生产,以确保稳定性和舒适性。

仪表板和控制台模具——CNC加工为注塑塑料零件创建模具。

装饰部件和原型——定制 CNC 加工支持快速原型制作和产品测试。

照明外壳——数控机床为前照灯和尾灯提供精确的形状。

电池外壳——由铝加工而成,重量轻但耐用。

电机外壳——CNC 加工确保电动传动系统的精度。

冷却系统——定制 CNC 零件支持电动汽车的先进热管理。

汽车行业是对精度、速度和创新要求最高的行业之一。CNC(计算机数控)机床拥有传统制造工艺无法比拟的显著优势。这些优势使 CNC 技术成为现代汽车生产的基石。

CNC 机器可达到微米级精度,确保发动机缸体、制动盘和传动齿轮等部件符合严格的公差。

可重复性保证了生产的每个零件都是相同的,这是装配线兼容性和车辆安全性的必要条件。

CNC 设备全天候运行,停机时间极短,大大提高了吞吐量。

能够通过一次设置加工多个零件,从而减少循环时间并提高交付速度。

自动化减少了对人工干预的依赖,确保了更快的大规模生产。

CNC 机器可以在快速成型和大批量生产之间无缝切换。

汽车工程师可以快速测试新设计,尤其是电动汽车 (EV) 和轻型零件。

这种灵活性缩短了产品开发周期并加速了创新。

CNC 加工通过优化切割路径最大限度地减少材料浪费。

通过自动化原本需要多名熟练机械师才能完成的复杂操作来降低劳动力成本。

尽管前期成本较高,但由于效率提高和废品减少,长期投资回报率非常可观。

高精度加工提高了关键安全部件的耐用性和性能。

稳定的质量降低了零件故障的风险,确保了发动机、悬架和制动系统的可靠性。

最终有助于实现更安全、更持久的车辆。

CNC 机器可以加工多种材料,包括铝、钢、钛、塑料和复合材料。

支持轻量化汽车设计,以提高燃油效率和电动汽车性能。

尽管 CNC 机床对于生产高质量的汽车零部件至关重要,但制造商仍面临着可能影响成本、效率和可持续性的若干挑战。

数控机床的前期成本是一大障碍,尤其对于中小型汽车供应商而言。采购多轴机床、先进的刀具和 CAD/CAM 软件需要大量资金。除了购置成本之外,刀具磨损、校准、能耗和冷却液使用等运营成本也持续增加压力。虽然长期投资回报率较高,但高昂的财务门槛阻碍了一些公司的采用。

CNC 加工并非完全的“一键式”制造。熟练的机械师和程序员对于创建精确的 G 代码、优化切削策略和处理故障排除至关重要。然而,许多地区面临着合格 CNC 技术人员短缺的问题。新型 CNC 软件和多轴加工的快速发展也意味着需要持续的培训。对于全天候运营的汽车工厂来说,熟练劳动力的短缺很快就会成为瓶颈。

数控机床必须保持最佳状态才能提供始终如一的精度。定期维护、刀具更换和校直检查至关重要,但这些都需要付出代价。意外故障在汽车行业尤其有害,因为该行业的生产线采用准时制生产。即使是短暂的停机也可能延误数千个零件的生产,从而导致供应链中断和财务损失。预测性维护解决方案正在涌现,但并非所有制造商都已将其集成。

随着汽车制造商转向更环保的制造方式,数控加工因其环境影响而面临严格审查。该工艺会产生大量金属切屑,需要使用必须妥善处理的切削液,并且会消耗大量电力。汽车原始设备制造商 (OEM) 要求其供应商采用更清洁、更可持续的生产方法。这促使数控加工车间探索节能机床、干式加工技术和回收系统,以在更具环保意识的市场中保持竞争力。

随着汽车行业的快速发展,数控机床也正在进入一个新时代。从电动汽车 (EV) 到人工智能驱动的智能工厂,数控加工的作用正在不断扩展,并适应未来的需求。以下是塑造 2025 年及以后数控加工的关键趋势:

汽车制造商越来越多地将数控机床与机械臂和自动化处理系统结合起来。

自动化使零件能够在机器之间无缝移动,减少人为干预、周期时间和错误。

这一趋势支持发动机零件、电动汽车电机外壳和精密齿轮等复杂部件的大批量生产。

数控机床正在成为利用人工智能和物联网连接的智能制造生态系统的一部分。

来自机器的实时数据可以监控刀具磨损、预测维护需求并自动优化切削参数。

人工智能驱动的 CNC 操作可提高效率、准确性和正常运行时间,同时降低与计划外停机相关的成本。

5 轴和混合 CNC 机床正在成为汽车生产的标准,允许在单一设置中加工复杂的几何形状。

混合机器结合了增材(3D 打印)和减材(铣削/车削)工艺,非常适合轻型电动汽车组件和原型。

这减少了生产步骤,缩短了交货时间,并实现了更具创新性的车辆设计。

电动汽车和自动驾驶汽车的兴起推动了对专用 CNC 加工零件的需求,包括电池外壳、电动机和传感器支架。

CNC 机床可以精确加工铝和复合材料等轻质材料,从而提高能源效率和性能。

随着电动汽车的普及,CNC加工将在支持新的动力传动系统架构和车辆创新方面发挥关键作用。

环境问题和更严格的法规正在推动数控加工走向绿色制造实践。

节能机器、干切削以及切屑和切削液的回收正在成为行业标准。

汽车制造商越来越期望供应商采用环保的 CNC 工艺,这使得可持续性成为一个关键的竞争因素。

CNC Yangsen 提供专为汽车行业设计的全面 CNC 加工解决方案,支持各种零部件,包括发动机和悬架部件以及电动汽车零部件。我们的高精度机床确保始终如一的质量和可靠性,而灵活的制造能力则可实现快速原型设计和大规模生产。通过为大品牌提供经济高效的替代方案,并提供全面的安装、培训和维护支持,CNC Yangsen 助力汽车制造商高效可靠地实现卓越成果。

CNC 机床已经彻底改变了汽车行业,使制造商能够实现无与伦比的精度、速度和效率。从发动机零部件到电动汽车创新,CNC 加工将继续推动汽车制造业的未来发展。

在 CNC Yangsen,我们致力于提供尖端的 CNC 加工解决方案,以满足汽车行业日益增长的需求。如果您希望简化生产流程、提高零件质量并降低成本,请立即联系我们!