CNC milling machines are widely used in modern manufacturing for producing precise metal parts in industries such as automotive, aerospace, mold making, and general machining. Compared with manual milling, CNC milling offers higher efficiency, greater consistency, and greater repeatability.

But in real production, a CNC milling machine's performance is not decided only by spindle speed or travel size. It mainly depends on the quality of its key internal components—such as the machine frame and bed, spindle, linear guideways, ball screws, CNC controller, and tool changing system. These vital parts directly affect rigidity, vibration control, positioning accuracy, surface finish, and long-term reliability.

In this article, we will explain the key components of a CNC milling machine and show why each is essential to machining performance and productivity.

A CNC milling machine works as a complete machining system. The CNC controller reads the machining program, then coordinates the spindle rotation and axis movements to remove material accurately and efficiently. Every machining result—accuracy, surface finish, cycle time, and stability—comes from how well the key systems work together.

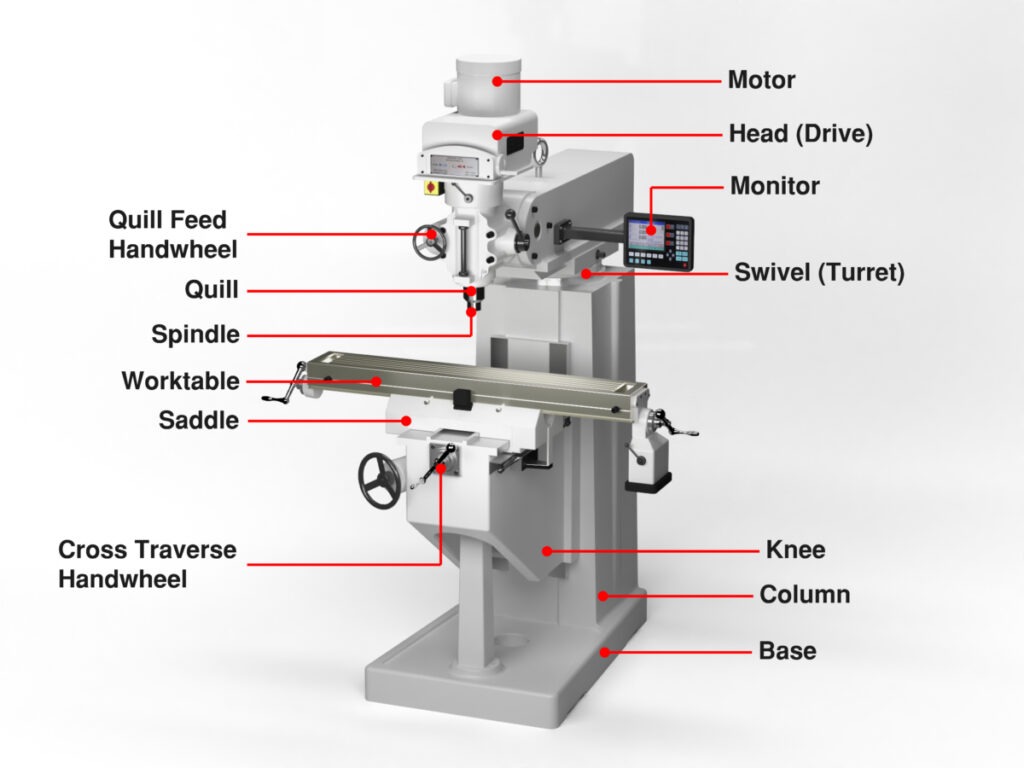

From a high-level view, the structure of a CNC milling machine can be divided into several major functional areas:

Motion System

This system controls the movement of the X/Y/Z axes. It ensures smooth travel, stable feed rate, and accurate positioning during cutting operations.

Spindle System

The spindle provides the cutting power by rotating the tool at a controlled speed and torque. It plays a direct role in cutting stability and surface quality.

Control System

The CNC controller is the “brain” of the machine. It manages motion coordination, machining logic, tool offsets, and process control to ensure consistent results.

Tool System

This includes tool holding, tool storage, and tool changing functions. It supports multi-step machining and improves automation and production efficiency.

In short, each vital part supports the machine's overall performance. When these systems are well-matched, the CNC milling machine can deliver better accuracy, stronger stability, and higher productivity.

To better understand how a CNC milling machine delivers precision and productivity, its key components can be grouped into four main categories. Each category plays a different role in machining performance, and together they determine the machine's overall stability, accuracy, and efficiency.

Structural components form the foundation of the machine. They support the cutting load and maintain rigidity during heavy machining.

Typical structural parts include:

Machine frame

Bed/base

Column and moving structure

These parts mainly affect vibration absorption, rigidity, and long-term stability.

This group is responsible for axis movement and positioning control. It directly influences machining accuracy and repeatability.

Typical motion and drive components include:

Linear guideways

Ball screws

Servo drive transmission (related system)

These parts mainly determine feed smoothness, positioning precision, and motion stability.

These components directly connect to the cutting process. They impact cutting capability, machining efficiency, and tool management during production.

Typical cutting and tool-related parts include:

Spindle

Tool holder interface (related system)

Automatic Tool Changer (ATC)

Tool magazine

This category mainly affects cutting power, tool change efficiency, and productivity.

Control and feedback components ensure the machine can run accurately and consistently according to the program. They are essential for stable automation and long-term machining reliability.

Typical control and feedback components include:

CNC controller

Encoders and feedback systems (related system)

Electrical control and servo system (related system)

These parts mainly affect motion coordination, machining consistency, and process control reliability.

The machine frame and bed are the foundation of a CNC milling machine. They support all major assemblies such as the spindle head, worktable, guideways, and drive system. During machining, cutting forces continuously act on the structure, so rigidity and stability are critical.

A high-quality frame and bed help to:

maintain structural rigidity under heavy cutting loads

reduce vibration and minimize chatter during milling

keep geometric accuracy stable over long machining cycles

If the machine structure is weak, it may lead to poor surface finish, unstable tolerance control, and faster wear on key moving components.

The spindle is one of the most important performance parts of a CNC milling machine. It drives the cutting tool rotation and directly determines cutting stability and machining capability.

The spindle affects machining performance through:

speed (supports high-efficiency finishing)

torque (supports heavy roughing and hard material cutting)

bearing quality and thermal stability (affects accuracy and lifespan)

A stable spindle helps achieve smoother surface finish, better dimensional consistency, and longer tool life—especially in high-speed or continuous production.

Linear guideways guide the movement of machine axes and ensure smooth and precise travel. They are essential for maintaining stable positioning accuracy and reducing motion errors during cutting.

Linear guideways contribute to:

smooth axis motion with low friction

high stiffness under load to support stable milling

better repeatability for batch machining

If guideways lack rigidity or precision, the machine may suffer from vibration, uneven feed movement, and reduced accuracy over time.

Ball screws convert servo motor rotation into accurate linear movement for axis feed and positioning. They are key parts that influence precision, repeatability, and long-term machining consistency.

Ball screws mainly provide:

precise positioning for each axis movement

stable feed transmission during cutting

improved repeatability for mass production

If ball screws wear out or have poor accuracy, common issues include backlash, dimensional variation, and reduced contour accuracy—especially in detailed milling and drilling operations.

The CNC controller is the “brain” of the CNC milling machine. It reads the machining program and controls all axis movements, spindle operations, and tool functions in a coordinated way.

A CNC controller is critical for:

motion coordination and interpolation accuracy

feed control during complex contour machining

process stability and machining consistency

supporting automation functions such as tool change and offsets

Even with strong mechanical parts, a weak controller may reduce machining efficiency, limit motion smoothness, or cause instability in precision machining processes.

An Automatic Tool Changer (ATC) is an essential component for modern CNC milling automation. It enables fast tool switching without manual operation, improving productivity in multi-step machining.

The ATC helps to:

Reduce tool change time and operator workload

support multiple machining operations in one cycle

increase production efficiency and consistency

A reliable ATC system is especially important for batch production, where stable and repeatable tool changes directly affect uptime and machining flow.

The tool magazine is the storage system that holds multiple tools and works together with the ATC. It allows the machine to prepare and manage tools efficiently during continuous machining.

A tool magazine supports:

organized tool storage for different machining steps

continuous production without frequent manual tool loading

faster cycle time for multi-tool parts

If the tool magazine system is unstable, it may cause tool selection errors, tool change interruptions, or reduced automation reliability—impacting both productivity and machining safety.

A CNC milling machine is not defined by one single “best” component. Real machining performance comes from how well the vital parts work together as a complete system. Each part has its own role, but they must stay in balance to achieve stable accuracy, high efficiency, and reliable production.

Here is how the key components coordinate during machining:

The CNC controller acts as the command center. It reads the program and sends instructions to control axis movements, spindle speed, feed rate, and tool change actions.

The ball screws and linear guideways execute the controller's commands by providing smooth, accurate axis motion. They ensure the machine can position correctly and maintain repeatability during continuous cutting.

The machine frame and bed support the entire structure. They resist cutting forces, absorb vibration, and keep the geometry stable, especially during heavy milling or long-time machining.

The spindle performs the actual cutting work. It must deliver stable speed and torque while maintaining precision, which directly affects surface finish and machining consistency.

The tool magazine and ATC system make automation possible. They store tools and switch them quickly, allowing one machine to complete multiple operations without manual interruption.

In short, CNC milling performance depends on the coordination between mechanical rigidity, motion accuracy, spindle stability, and control automation. A machine achieves its best results only when these vital parts are well-matched and designed to work as one integrated system.

The vital parts of a CNC milling machine are not just basic hardware—they directly determine how well the machine performs in real production. From tolerance control to cycle time and long-term reliability, the quality and coordination of these components affect every machining result.

Machining accuracy depends on the machine's ability to position and cut correctly, repeatedly, and consistently.

The machine frame and bed provide rigidity to prevent deformation during cutting.

Linear guideways and ball screws control precise axis movement and reduce positioning errors.

The CNC controller ensures accurate motion coordination and stable machining execution.

If any of these components are weak, the machine may struggle to hold tight tolerances, especially in high-precision milling or long-cycle machining.

Surface quality is not only affected by cutting tools—it also depends heavily on machine stability.

A stable spindle reduces vibration and supports smooth cutting.

High-quality guideways enable steady feed motion without shaking or sticking.

A rigid machine structure helps suppress chatter, improving finishing results.

When these parts work well together, the machine can produce cleaner surface finishes with fewer tool marks.

In real workshops, reliability often matters more than maximum speed. A CNC milling machine must stay stable after long-term operation, not only on day one.

Strong structural parts reduce long-term misalignment risk.

Durable ball screws and guideways maintain accuracy longer with less wear.

A reliable control system improves stability and reduces unexpected errors.

Stable ATC and tool magazine systems lower the chance of tool change failures.

Better component quality usually means fewer breakdowns and longer machine service life.

Higher productivity is not only about faster feed rates—it is about keeping the machine running efficiently with less downtime.

A reliable spindle supports higher cutting efficiency and stable performance.

ATC + tool magazine reduces manual work and shortens cycle time.

Accurate motion parts reduce rework, scrap rate, and inspection pressure.

Stable machine systems allow continuous unmanned or semi-automated machining.

In short, high-quality vital parts help improve uptime, shorten machining cycles, and deliver more consistent output per shift.

What are the most important parts of a CNC milling machine?

The most important parts include the machine frame and bed, spindle, linear guideways, ball screws, CNC controller, ATC, and tool magazine. These determine rigidity, precision, automation, and overall machining performance.

Which components most affect machining accuracy?

Accuracy mainly depends on structural rigidity, precision of guideways and ball screws, and controller performance with feedback systems. High-quality parts ensure tight tolerances and repeatable results.

Can upgrading certain parts improve machine performance?

Yes. Upgrades such as high-precision ball screws, better spindle, advanced CNC controller, or improved ATC can enhance accuracy, surface finish, and automation. Performance gains depend on the machine's overall design and structural support.

What part affects surface finish the most?

Surface finish is mainly influenced by spindle stability, linear guideways, ball screws, and frame rigidity. A stable spindle and smooth axis motion reduce chatter marks and improve finish quality.

How does the ATC and tool magazine impact productivity?

A reliable ATC and tool magazine allow fast, automated tool changes, enabling multi-step machining without manual intervention. This reduces cycle time, increases production efficiency, and minimizes operator dependency.

Should I consider components when comparing CNC machine brands?

Absolutely. Comparing specifications like travel size or spindle speed is not enough. Evaluating the quality of key parts and their integration—frame, spindle, guideways, ball screws, controller, and ATC—gives a clearer picture of real-world machining performance and reliability.