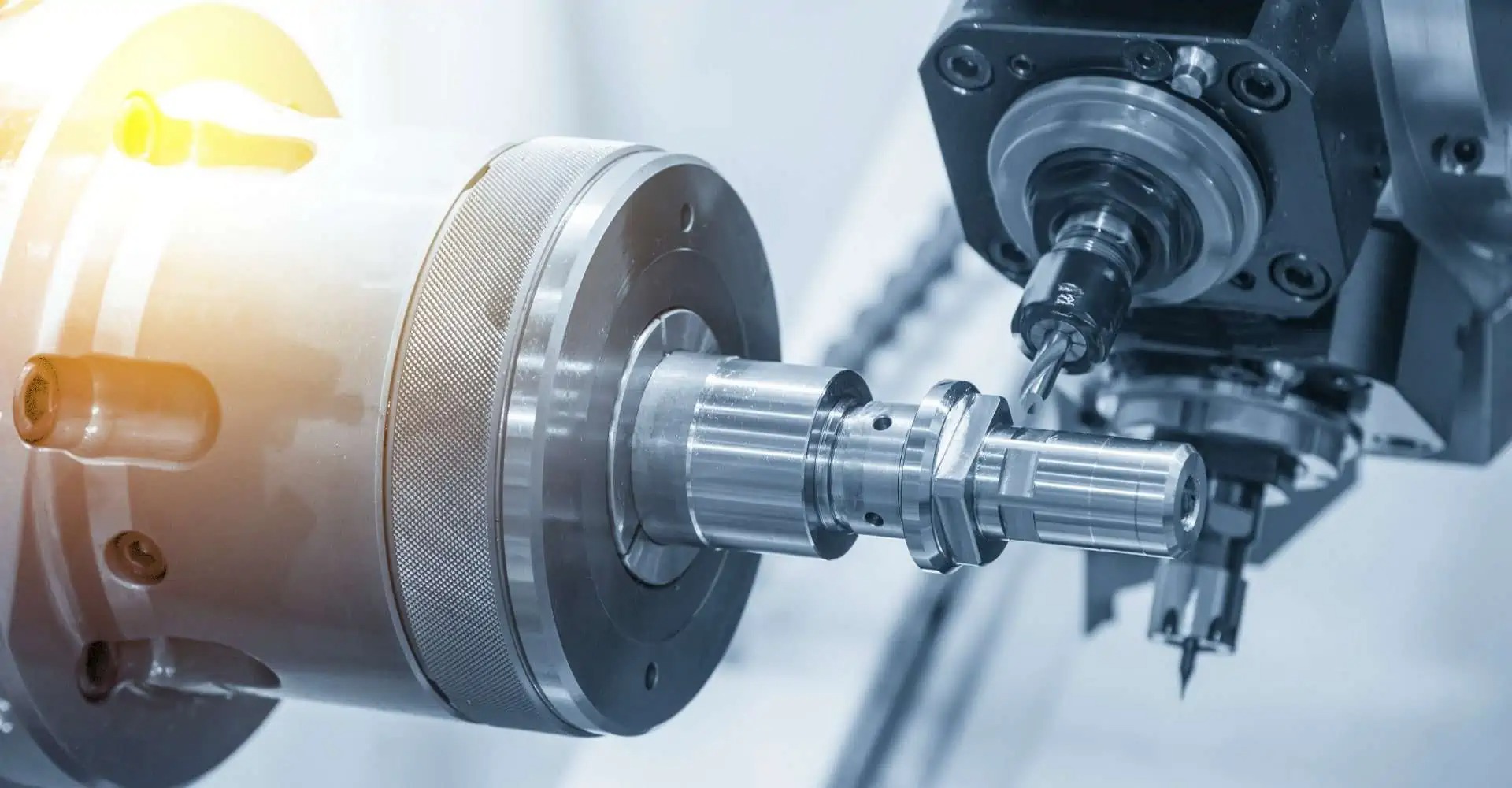

高精度铣削在现代制造业中扮演着重要角色,因为现代制造业对公差要求极高,质量稳定性要求也极高。航空航天、医疗器械、汽车零部件和模具制造等行业都依赖精密加工来满足严格的性能标准。与标准数控铣削相比,高精度铣削更注重微米级精度、稳定的重复性和优异的表面光洁度。要实现这些目标,需要刚性数控机床结构、可靠的运动控制系统、高质量的刀具以及优化的加工策略。

随着产品变得越来越复杂和性能驱动,精密铣削有助于制造商提高效率、减少缺陷,并在全球生产中保持具有竞争力的质量。

高精度铣削是一种旨在生产尺寸精度极高的零件的加工工艺,其精度通常在±3–6 μm(±0.003–0.006 mm)以内,具体取决于材料、刀具和应用要求。这种精度水平可确保稳定的公差、优异的重复性和高质量的表面光洁度,尤其是在加工复杂形状或关键功能表面时。

与传统数控铣削相比,高精度铣削对机床刚性、热稳定性、运动控制精度和切削参数的要求更高。它广泛应用于模具制造、航空航天、医疗器械、汽车零部件和精密工程等行业,在这些行业中,即使是微小的偏差也会影响产品的性能、装配精度或使用寿命。

高精度铣削需要一套数控系统,该系统旨在整个加工过程中保持精度、稳定性和重复性。以下核心要素对于实现微米级公差至关重要。

坚固耐用的铸铁机架为精密加工奠定了基础。加强筋的内部设计提高了刚性,最大限度地减少了重切削过程中的结构变形。凭借强大的减振能力,即使在长时间的加工循环中,该机床也能保持稳定性并实现一致的精度。

精密线性导轨确保平稳、可重复的轴向运动,而高精度滚珠丝杠则有助于保持定位精度并最大限度地减少反冲。直接伺服电机耦合提高了运动响应速度并消除了误差累积,从而支持高精度铣削所需的稳定、精确的刀具路径。

高速、热稳定性高的主轴确保刀具平稳旋转和切削条件一致。BT、BBT 或 HSK 等刀具接口系统可提高刚性并有效控制跳动。凭借闭环反馈和热补偿功能,数控系统可在连续或高速加工过程中保持精度。

刀具和夹具是实现高精度铣削的关键因素。即使使用先进的数控机床,刀具选择不当或夹具不稳定也会导致振动、尺寸偏差、颤纹和表面光洁度不一致。精密加工取决于合适的切削刀具、最佳的刀具夹持系统以及稳定且可重复的夹紧策略的结合。

整体硬质合金立铣刀因其刚性和耐磨性而被广泛应用于精密铣削。根据材料和表面光洁度要求,可以选择PCD、CBN、涂层硬质合金或金刚石涂层刀具,以提高切削稳定性、降低发热量并延长刀具寿命。刀具几何形状(例如槽形、螺旋角和圆角半径)也会影响排屑和加工质量。选择合适的刀具类型可确保在高精度精加工过程中实现稳定的切削和可预测的性能。

刀柄的精度直接影响跳动、振动和刀具磨损。热缩刀柄和液压刀柄是精密加工的首选,因为它们通常能实现≤2–3 μm的跳动,从而实现更平滑的切削和更精细的表面光洁度。在高主轴转速下,刀具平衡同样重要,有助于防止颤振并提高尺寸重复性。

刚性且可重复的夹紧系统确保工件在整个加工过程中保持稳定。精密虎钳、零点夹紧系统和模块化夹具可在保持精度的同时实现快速定位。对于薄壁或易碎零件,真空夹具或软爪有助于避免变形。其目标是在牢固夹持工件的同时,最大限度地减少应力并保持一致的几何对准。

采用较小的步距并控制切屑负载有助于降低切削力和刀具挠度。这种策略可以提高精加工过程中的稳定性,并有助于获得一致的尺寸精度,尤其是在加工精细表面时。

高速加工能够以更低的切削压力实现更平稳的运动。更高的主轴转速结合更轻的切削力有助于获得更好的表面光洁度并减少热量积聚,从而提高加工精度和刀具寿命。

自适应刀具路径可保持刀具持续啮合,并最大限度地减少方向的突变。这种方法可降低振动,提高加工过程中的可预测性,并有助于在复杂形状或多曲面特征上保持公差稳定性。

粗加工侧重于高效去除材料,而精加工则采用优化的参数来实现最终尺寸。将这两个阶段分开有助于稳定零件、降低应力,并确保高重复性和精细的表面质量。

| 材料 | 特征 | 精密铣削注意事项 |

| 铝 | 重量轻、加工性能好、切削响应快 | 使用高主轴转速、锋利的硬质合金或 PCD 刀具,并确保切屑顺利排出,以避免积屑瘤并保持表面光洁度。 |

| 不锈钢 | 切削过程中硬度更高,热量产生更多。 | 涂层硬质合金刀具、可控进给速度和稳定的冷却液流动有助于减少热变形并保持公差稳定性。 |

| 钛 | 强度高,导热系数低,易产生振动 | 需要刚性刀具夹持、较低的切削速度、一致的切屑负荷和热控制切削策略,以防止刀具磨损和变形。 |

| 硬化钢 | 用于模具和精密工具,强度高 | 精加工通常需要 CBN 或陶瓷刀具、轻微的精加工工序以及精确的主轴控制,才能获得精细的表面光洁度和一致的公差。 |

精密铣削广泛应用于模具制造领域,该领域对精细细节、光滑表面和严格公差的要求极高。稳定的加工策略和精确的精加工能够确保模具满足尺寸标准,并减少抛光或手动调整等后处理工序。

航空航天零部件通常需要复杂的几何形状和高精度,以确保安全性和性能。高精度铣削能够为涡轮机部件、支架、壳体和结构件提供一致的公差、轻量化的结构以及可靠的装配。

医疗器械,例如植入物、手术器械和牙科修复体,需要具备高度的重复性和严格的尺寸精度。高精度铣削能够可靠地生产复杂形状的部件,同时保持适用于医疗应用的表面质量。

在汽车和精密工程领域,高精度铣削确保发动机零件、变速器部件和高性能机械组件的精确生产。可靠的精度保障了产品的功能性、互换性和批量生产的一致性。

振动和颤动是精密铣削中常见的问题,会导致尺寸误差、表面光洁度差和刀具寿命缩短。其原因可能包括夹具不牢固、刀具悬伸过长、刀具不平衡或切削参数不当。解决方法包括使用刚性刀具夹持系统、缩短刀具长度、使用平衡刀具以适应高速旋转,以及优化进给速度和主轴转速。调整步距值和使用更平滑的刀具路径也有助于在精加工过程中保持切削稳定性。

刀具磨损或过大的跳动会对零件的公差、几何精度和表面光洁度产生负面影响。材料硬度、切削速度不当、润滑不足或刀柄质量差等因素都会加速刀具磨损。为最大限度地减少这些问题,应使用高性能硬质合金或涂层刀具,并配合热缩或液压刀柄,以确保跳动量在规格范围内。定期进行刀具监测、预调和定期更换有助于确保切削质量的稳定性和可重复性。

长时间加工过程中温度的变化会导致工件和机床部件发生热变形,进而造成公差漂移或批次间尺寸不一致。解决方案包括使用带有热补偿系统的机床、施加适当的冷却液流量以及确保车间温度稳定。加工前的预热循环和逐步精加工也有助于在加工精密零件时保持尺寸稳定性。

薄壁零件或刚度较差的材料在切削压力下可能发生变形,导致精度下降、波纹或表面光洁度不一致。采用优化的加工力、较小的切削深度和稳定的切屑负荷有助于最大限度地减少变形。工件夹具也起着至关重要的作用——软爪、额外的支撑点、真空夹具或定制的夹紧方案可以防止微动,并在最终精加工过程中保持几何精度。

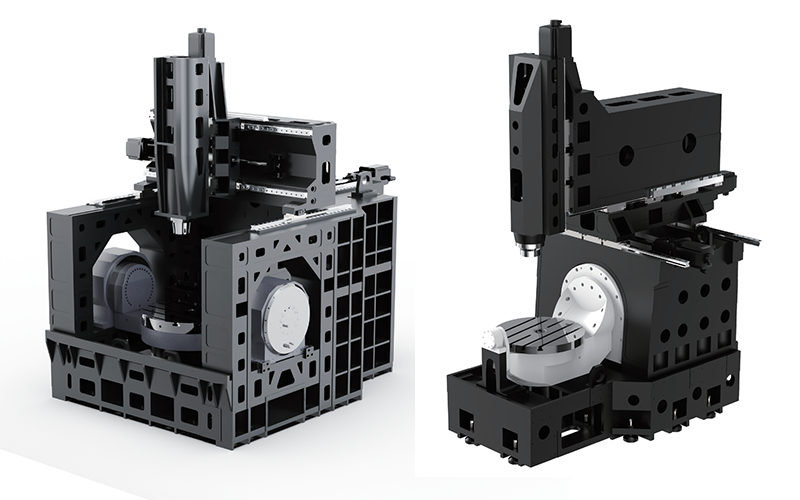

五轴转轮式加工中心 这些机床非常适合加工具有多个表面、角度特征或复杂轮廓的精密零件。其耳轴结构可实现多轴同步运动,从而减少装夹次数并提高几何精度。凭借稳定的刚性、较短的刀具长度和流畅的运动控制,这些机床有助于在高价值零件上实现更严格的公差和更佳的表面光洁度。

高速 立式加工中心 这些机床非常适合精密加工、模具部件以及中小尺寸零件的加工。其紧凑的结构和高主轴转速确保了平稳的切削性能和较低的切削压力。凭借精确的运动控制和热稳定性,这些机床在精密加工应用中能够保持重复性并获得良好的表面质量。

桥式或 龙门式数控机床 这些机床结构刚性强,加工范围广,适用于模具、冲模和大型精密零件的加工。其稳定的框架设计最大限度地减少了加工过程中的变形,尤其是在重切削或长循环加工的情况下。凭借先进的驱动系统和定位精度,这些机床能够在需要大面积高精度加工的应用中提供可靠的性能。

高精度铣削的精度能达到多高?

高精度铣削通常能将公差控制在±0.003–0.01毫米以内,具体精度取决于材料、刀具和机床配置。热稳定性、主轴状态和刀具跳动等因素也会影响最终精度。

刀具跳动真的会影响精密加工吗?

是的。即使是 3–5 μm 的跳动也会影响加工质量、公差一致性和刀具寿命。使用热缩或液压刀柄有助于保持较低的跳动,并提高高精度加工过程中的稳定性。

为什么热控制在精密加工中如此重要?

切削过程中产生的热量会导致机床和工件的热膨胀,从而造成尺寸偏差。冷却液的稳定性、预热程序和热补偿有助于在长时间的加工周期中保持精度。

做精密加工一定要用五轴机床吗?

不一定。三轴或四轴机床对于简单的几何形状也能获得精确的加工结果。然而,五轴加工在减少装夹次数或加工复杂的曲面过渡时,能显著提高精度。

为什么要将精密铣削中的粗加工和精加工分开进行?

粗加工可能会引入内应力、热量或轻微变形。采用优化参数的专用精加工工序可确保最终精度、一致的公差和更好的表面光洁度。

高精度铣削在现代制造业中扮演着重要角色,因为现代制造业对精度、重复性和表面质量稳定性都有很高的要求。通过合理的机床配置、刀具系统、加工策略和过程控制,制造商可以在不同的行业和材料加工中实现一致的公差和高生产可靠性。

随着对复杂、高价值零部件的需求不断增长,投资精密加工能力对于提高效率和满足严格的质量要求至关重要。

如果您希望提升加工性能或为精密应用选择合适的数控解决方案,我们的团队可以提供支持和量身定制的建议。